RESEARCH PROFILE

The team is involved in synthesis, processing and testing of new polymer materials. Our areas of interest include new materials based on bioactive and biodegradable polymers. We are conducting studies involving synthetic and natural hydrogels, new biodegradable and edible packaging materials and a wide range of composite materials having interesting new properties.

We are working on new food packaging materials with the addition of active substances extracted from plants. We also design and physico-chemically characterize of three-dimensional materials based on natural polymers like silk fibroin and chitosan.

GROUP MEMBERS

Head of the Research Group

dr hab. Jacek Nowaczyk, prof. UMK

tel.: +48 (56) 611 48 38; e-mail: janowa@umk.pl

room no. 262 (building B)

Group members:

dr hab. Ewa Olewnik-Kruszkowska, prof. UMK

tel.: +48 (56) 611 22 10; e-mail: olewnik@umk.pl

room no.203 (building B)

dr Magdalena Gierszewska

tel.: +48 (56) 611 45 24; e-mail: mgd@umk.pl

room no. 213a (building B)

dr Izabela Koter

tel.: +48 (56) 611 44 07; e-mail: ikoter@umk.pl

room no. 67 (building B)

PhD students:

mgr Elżbieta Czarnecka

e-mail: elzbieta.czarnecka@tzmo-global.com

room no. 210 (building B)

mgr inż. Weronika Kujawa

e-mail: weronika.kujawa@doktorant.umk.pl

room no. 201 (building B)

PROJECTS, GRANTS

Recent research projects:

1) New biodegradable packaging materials with antibacterial properties for food and medical materials

2) Preparation and physicochemical characterization of new superabsorbent polymers

3) Cement-based composites filled with polymeric and photocatalytic additives. – IDUB – project INCOOP

4) Dielectric elastomer-based composites. – Grant Ministra Obrony Narodowej we Współpracy z Akademią Marynarki Wojennej n numer M-1-1-1-024/2018

5) Is chitosan dialdehyde a good substance to modify physico-chemical properties of biopolymeric materials?

6) Active compounds extracted from olive leaves as additives to biodegradable materials

SELECTED PUBLICATIONS

Alicja Tymczewska, Aleksandra Szydłowska-Czerniak, Jacek Nowaczyk,

Bioactive packaging based on gelatin incorporated with rapeseed meal for prolonging shelf life of rapeseed,

Food Packaging and Shelf Life, (29) 2021: 100728,

https://doi.org/10.1016/j.fpsl.2021.100728.

Abstract: A biodegradable and antioxidant films were prepared from gelatin enriched with rapeseed meal (RM) and their applicability as a packaging materials for rapeseed was investigated. The effect of films’ composition on their morphology, optical, and mechanical characteristics was studied and compared. Three extraction-dependent: 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), 2,2-diphenyl-1-picrylhydrazyl (DPPH), and cupric ion reducing antioxidant capacity (CUPRAC) methods as well as extraction-free QUENCHER (QUick, Easy, New, CHEap and Reproducible) procedure were applied to determine the antioxidant capacity (AC) of the obtained gelatin films. The synthesized films were evaluated as packages for rapeseed stored under accelerated conditions for 7 and 14 days. After 2 weeks of storage, the highest antioxidant properties had rapeseed packed in a new bag and oil pressed from stored seeds. Therefore, gelatin film incorporating RM can be used as a functional packaging to protect oilseeds with high fat content from oxidation processes.

Keywords: Active packages; Gelatin; Rapeseed meal; Antioxidant capacity; Oil quality; Shelf life

Ewa Olewnik-Kruszkowska, Magdalena Gierszewska, Sylwia Grabska-Zielińska, Joanna Skopińska-Wiśniewska, Ewelina Jakubowska.

Examining the impact of squaric acid as a crosslinking agent on the properties of chitosan-based films.

International Journal of Molecular Sciences 22(7) 2021: 3329,

https://doi.org/10.3390/ijms22073329

Abstract: Hydrogels based on chitosan are very versatile materials which can be used for tissue engineering as well as in controlled drug delivery systems. One of the methods for obtaining a chitosan-based hydrogel is crosslinking by applying different components. The objective of the present study was to obtain a series of new crosslinked chitosan-based films by means of solvent casting method. Squaric acid—3,4-dihydroxy-3-cyclobutene-1,2-dione—was used as a safe crosslinking agent. The effect of the squaric acid on the structural, mechanical, thermal, and swelling properties of the formed films was determined. It was established that the addition of the squaric acid significantly improved Young’s modulus, tensile strength, and thermal stability of the obtained materials. Moreover, it should be stressed that the samples consisting of chitosan and squaric acid were characterized by a higher swelling than pure chitosan. The detailed characterization proved that squaric acid could be used as a new effective crosslinking agent.

Ewa Olewnik-Kruszkowska, Magdalena Gierszewska, Agnieszka Richert, Sylwia Grabska-Zielińska, Anna Rudawska, Mohamed Bouaziz.

Antibacterial films based on polylactide with the addition of quercetin and poly(ethylene glycol).

Materials 14(7) 2021: 1643,

https://doi.org/10.3390/ma14071643

Abstract: A series of new films with antibacterial properties has been obtained by means of solvent casting method. Biodegradable materials including polylactide (PLA), quercetin (Q) acting as an antibacterial compound and polyethylene glycol (PEG) acting as a plasticizer have been used in the process. The effect of quercetin as well as the amount of PEG on the structural, thermal, mechanical and antibacterial properties of the obtained materials has been determined. It was found that an addition of quercetin significantly influences thermal stability. It should be stressed that samples containing the studied flavonoid are characterized by a higher Young modulus and elongation at break than materials consisting only of PLA and PEG. Moreover, the introduction of 1% of quercetin grants antibacterial properties to the new materials. Recorded results showed that the amount of plasticizer did not influence the antibacterial properties; it does, however, cause changes in physicochemical properties of the obtained materials. These results prove that quercetin could be used as an antibacterial compound and simultaneously improve mechanical and thermal properties of polylactide-based films

Ewelina Jakubowska, Magdalena Gierszewska, Jacek Nowaczyk, Ewa Olewnik-Kruszkowska,

Physicochemical and storage properties of chitosan-based films plasticized with deep eutectic solvent,

Food Hydrocolloids, (108) 2020: 106007,

https://doi.org/10.1016/j.foodhyd.2020.106007.

Abstract: This paper concerns novel, biodegradable and nontoxic materials for food-packaging. In order to obtain these properties, chitosan (Ch) and choline chloride (ChCl)-based deep eutectic solvent (DES) with malonic acid (MA), were used. The use of ChCl-MA mixtures as a potential plasticizer of chitosan (DD = 72 and 83%) films was proposed. All films with DES content ranging from 0 to 80 wt% were successfully prepared by a solution casting method. The properties of the DES-modified films were compared to those of the unmodified chitosan films. The effect of DES content on the structural (FTIR, SEM and AFM methods), mechanical, thermal and barrier properties of chitosan films was studied. The addition of ChCl:MA resulted in a significant increase in the elasticity. Chitosan films containing 80 wt% of DES exhibits Young’s modulus lower by ca. 2400 MPa in comparison to the native chitosan films. According to the AFM images, chitosan-DES films possess higher roughness compared to the unmodified ones. Thermal properties were also influenced by the presence and content of DES due to the lower thermal stability of ChCl:MA mixture. Evaluation of water vapor permeability confirmed an increase in this parameter for all DES-modified films. Observed changes in chitosan properties increase the potential of this material being successfully used in food packaging.

Keywords: Chitosan film; Deep eutectic solvent; Choline chloride; Malonic acid; Mechanical properties; Food packaging

Ewa Olewnik-Kruszkowska, Weronika Brzozowska, Arkadiusz Adamczyk, Magdalena Gierszewska, Izabela Wojtczak, Myroslav Sprynskyy.

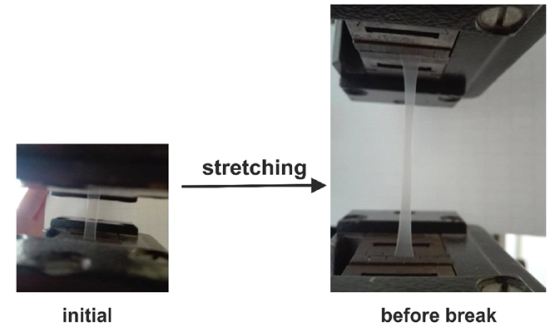

Effect of diatomaceous biosilica and talc on the properties of dielectric elastomer based composites.

Energies 13(21) 2020: 5828,

Abstract: Currently, scientists are still looking for new polymeric materials characterized by improved mechanical, thermal as well as dielectric properties. Moreover, it should be stressed that new composites should be environmentally friendly. For this reason, the aim of this work is to establish the influence of natural fillers in the form of diatomaceous biosilica (B) and talc (T) on the properties of dielectric elastomer (DE)-based composites. The dielectric elastomer-based materials have been tested taking into account their morphology, thermal and mechanical properties. Moreover, the dielectric constant of the obtained materials was evaluated. Obtained results revealed that the presence of both diatomaceous biosilica and talc significantly increases dielectric properties while having no significant effect on the mechanical properties of the obtained composites. It should be stressed that the performed analyses constitute a valuable source of knowledge on the effective modification of the thermal and dielectric properties of newly obtained materials

Ewa Olewnik-Kruszkowska, Iwona Tarach, Agnieszka Richert, Marcin Cichosz, Izabela Koter, Jacek Nowaczyk,

Physicochemical and barrier properties of polylactide films including antimicrobial additives,

Materials Chemistry and Physics, (230) 2019: 299-307,

https://doi.org/10.1016/j.matchemphys.2019.03.080.

Abstract: This study gives insight into basic physicochemical properties of new polylactide-based materials containing 1%wt of one of the three polyhexamethylene guanidine (PHMG) derivatives: PHMG stearate (LS), PHMG in granular polyethylene wax (LW) and PHMG sulfanilic acid salt (LA). The resulting materials after processing into films were studied by means of gel permeation chromatography (GPC); infrared spectroscopy (FTIR), atomic force microscopy (AFM), differential scanning calorimetry (DSC) and thermogravimetry (TG). It was found that while PHMG does not react with the polymer matrix, compatibilizing additives such as sulfanilic acid, stearate salts and polyethylene wax interact with the polylactide. Sulfanilic acid initiates polymer crosslinking, stearate causes partial hydrolysis and polyethylene wax plasticises the polymer. LS composite shows the best barrier properties with a barrier characteristic of that of glass. The crystallinity of these materials decreases due to addition of PHMG with compatibilizing agent. The enthalpies of melting were found to be 21.5, 22.7 and 25.2 kJ/g for LA, LA and LW, respectively.

Keywords: Polylactide; Polyhexamethylene guanidine; Biodegradable composites; Thermal properties; Hemp oil; Peroxide number

Ewa Olewnik-Kruszkowska, Jacek Nowaczyk, Kornelia Kadac,

Effect of compatibilizig agent on the properties of polylactide and polylactide based composite during ozone exposure,

Polymer Testing, (60) 2017: 283-292,

https://doi.org/10.1016/j.polymertesting.2017.04.009.

Abstract: Compatibilizers belong to the most important internal factors which influence the degradation process of polymer matrix. For this reason in the current study, polylactide (L), polylactide with 5% of poly(ε-caprolactone) (LK) as compatibilizing agent and samples with 5%wt. of montmorillonite (MMT) (LS5 and LS5K respectively) before and after various time of ozone exposure have been analyzed. The results from infrared spectroscopy, gel permeation chromatography, atomic force microscopy, differential scanning calorimetry and thermogravimetric analysis have been presented. It has been established that microstructural changes during ozone exposure of the samples with the presence of compatibilizer increase in relation to the samples comprising PLA and PLA filled with montmorillonite. Moreover it has been determined that the introduction of poly(ε-caprolactone) into pure polymer as well as into PLA-montmorillonite material accelerates ozone-induced degradation, although it does not change the mechanism of the degradation process.

Keywords: Polylactide; Compatibilizer; Nanofiller; Ozone; Thermal properties

Ewelina Jakubowska, Magdalena Gierszewska, Jacek Nowaczyk, Ewa Olewnik-Kruszkowska,

The role of a deep eutectic solvent in changes of physicochemical and antioxidative properties of chitosan-based films,

Carbohydrate Polymers, (255) 2021: 117527,

https://doi.org/10.1016/j.carbpol.2020.117527.

Abstract: In this work deep eutectic solvent (DES), based on the mixture of choline chloride and lactic acid, were suggested as chitosan films plasticizers. The molecular structure and properties of films obtained using chitosan, with different degree of deacetylation and 0–80 wt.% DES content (ωDES), were studied by means of FTIR spectroscopy, SEM and AFM microscopy (films’ surface properties) together with optical characteristics, water vapor transmission rate (WVTR), water vapor permeability (WVP), tensile strength (TS) and elongation at break (Eb). Scanning electron micrographs revealed that all chitosan-DES films were smooth and uniform. DES significantly improves the film flexibility (Eb increases of ca. 160 % after incorporation of 80 wt.% DES), slightly decreases tensile strength and also improves antioxidative properties while simultaneously, increasing water vapor permeability (WVP). Films prepared in this study exhibit characteristics that qualify them for potential use as an active packaging material.

Keywords: Chitosan; Deep eutectic solvent (DES); Choline chloride (ChCl); Lactic acid (LA); Mechanical properties; Food packaging

Ewa Olewnik-Kruszkowska, Iwona Tarach, Izabela Koter, Agnieszka Richert, Jacek Nowaczyk, Magdalena Gierszewska,

Stability of polylactide as potential packaging material in solutions of selected surfactants used in cosmetic formulae,

Polymer Testing, (74) 2019: 225-234,

https://doi.org/10.1016/j.polymertesting.2019.01.007.

Abstract: Currently the use of different types of cosmetics is an integral part of our life. For this reason the stability of packaging materials in contact with popular cosmetic ingredients is crucial. In this work a study on the properties of polylactide (PLA) as potential packaging in selected surfactant solutions (sodium lauryl sulfate (SLS) and sodium laureth sulfate (SLES)) has been carried out. For referential purposes immersion in distilled water has also been conducted. After previously established time, the difference in mass of polymer films as well as in the average molecular weight of PLA has been measured. Moreover the changes in surface morphology and in thermal parameters of PLA have been studied. The results indicate that the most significant changes in the properties of the PLA as well as in pH of the studied mediums have been observed in the case of storage in SLES solution. This phenomenon occurs because the sodium laureth sulfate is responsible for the increase in acidity, resulting from the SLES self-hydrolysis. Obtained result can be useful for industry in order to protect cosmetic products and consumers.

Keywords: Polylactide; Packaging materials; Surfactants; SLS; SLES; Cosmetic product

Sylwia Grabska-Zielińska, Adrianna Sosik, Anna Małkowska, Ewa Olewnik-Kruszkowska, Kerstin Steinbrink, Konrad Kleszczyński, Beata Kaczmarek-Szczepańska, The Characterization of Scaffolds Based on Dialdehyde Chitosan/Hyaluronic Acid. Materials 14 (2021) 4993.

https://doi.org/10.3390/ma14174993

Abstract: In this work, two-component dialdehyde chitosan/hyaluronic acid scaffolds were developed and characterized. Dialdehyde chitosan was obtained by one-step synthesis with chitosan and sodium periodate. Three-dimensional scaffolds were prepared by the lyophilization method. Fourier transform infrared spectroscopy (FTIR) was used to observe the chemical structure of scaffolds and scanning electron microscopy (SEM) imaging was done to assess the microstructure of resultant materials. Thermal analysis, mechanical properties measurements, density, porosity and water content measurements were used to characterize physicochemical properties of dialdehyde chitosan/hyaluronic acid 3D materials. Additionally, human epidermal keratinocytes (NHEK), dermal fibroblasts (NHDF) and human melanoma cells (A375 and G-361) were used to evaluate cell viability in the presence of subjected scaffolds. It was found that scaffolds were characterized by a porous structure with interconnected pores. The scaffold composition has an influence on physicochemical properties, such as mechanical strength, thermal resistance, porosity and water content. There were no significant differences between cell viability proliferation of all scaffolds, and this observation was visible for all subjected cell lines.

Keywords: dialdehyde chitosan; hyaluronic acid; scaffolds; tissue engineering

ul. Gagarina 7, 87-100 Toruń

ul. Gagarina 7, 87-100 Toruń